As an Amazon Associate, I earn from qualifying purchases.

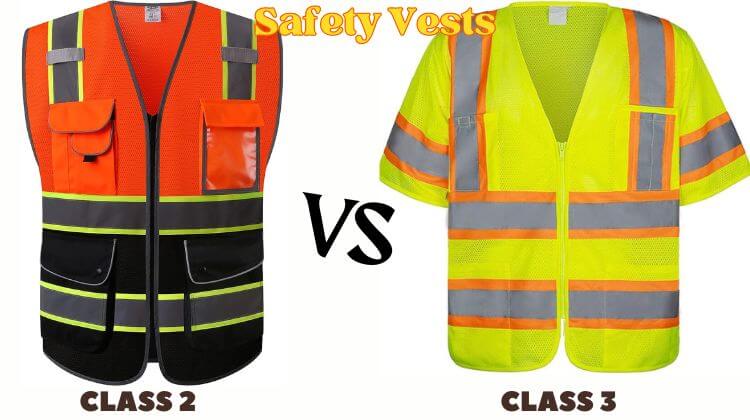

In worker safety, selecting the right protective gear is paramount. Safety vests, often worn in high-risk environments, come in various classes, with Class 2 and Class 3 being prominent options. This article dives into the nuanced comparison between Class 2 vs. Class 3 safety vests, illuminating their features, applications, and benefits. As a result, you can make an informed decision about enhanced worker protection.

Understanding Safety Vests

What is a Class 2 Safety Vest?

Class 2 safety vests are meant to provide greater visibility in environments with moderate traffic speeds and background complexity. They feature at least 775 square inches of reflective material and 201 square inches of high-visibility material. These vests are suitable for road construction, utility work, airport ground crews, and other settings with a moderate risk of accidents.

What is a Class 3 Safety Vest?

Class 3 safety vests offer the highest level of visibility. They are designed for environments with high traffic speeds and reduced visibility due to weather conditions or low light. These vests include a minimum of 1,240 square inches of reflective material and 310 square inches of high-visibility material. Those who work in low-visibility conditions, such as emergency responders and tow truck operators, should wear a Class 3 safety vest.

Difference Between Class 2 and Class 3 Safety Vest:

[wptb id=5702]Applications and Use Cases

Implementing Class 2 and Class 3 safety vests effectively requires understanding the context. Let’s delve into various scenarios where each type shines.

Class 2 Safety Vest Applications

- Construction Sites: Class 2 vests are commonly used by construction workers when working near equipment or vehicles.

- Parking Attendants: Parking attendants often wear Class 2 vests to ensure they are visible to drivers in parking lots.

- Warehouses: Workers in warehouses benefit from Class 2 vests to maintain visibility in bustling environments.

Class 3 Safety Vest Applications

- Nighttime Roadwork: Highway construction crews require Class 3 vests for maximum visibility during nighttime operations.

- Emergency Responders: Police officers, firefighters, and EMTs rely on Class 3 vests to be easily spotted in critical situations.

- Traffic Control: Flaggers directing traffic use Class 3 vests to ensure drivers can see them from a distance.

Pros and Cons Class 2 Safety Vests

Like any safety gear, Class 2 safety vests come with their own set of advantages and limitations.

Pros

Cons

Pros and Cons of Class 3 Safety Vests

Class 3 safety vests are revered for their high visibility but have specific attributes that should be considered.

Pros

Cons

Class 2 vest vs. Class 3: FAQs

Here are some common questions about Class 2 vs. Class 3 safety vests, answered concisely:

- Can I Use a Class 2 Vest in Low-Light Conditions? Yes, you can, but Class 2 vests are better suited for environments with moderate lighting. For low-light scenarios, a Class 3 vest is recommended.

- Are Class 3 Vests Always Sleeveless? No, Class 3 vests can have sleeves or be sleeveless. The inclusion of sleeves provides additional coverage and protection.

- Can I Wear a Class 2 Vest on the Highway? While you can wear a Class 2 vest on the highway, it might not provide the necessary visibility for high-speed traffic. In such cases, a Class 3 vest is the safer choice.

- Why Are Class 3 Vests Bulkier? Class 3 vests are bulkier due to their increased coverage and reflective material, ensuring maximum visibility. While they might be slightly less comfortable, they offer superior protection.

- Are There Situations Where Class 1 Vests Are Sufficient? Yes, Class 1 vests are suitable for low-risk environments with significant visibility enhancement, such as directing foot traffic in a parking lot.

Conclusion

Regarding worker safety, choosing between Class 2 and Class 3 safety vests is a crucial decision. Your decision should align with the specific demands of the work environment and lighting conditions. Class 2 vests are excellent for moderate-risk scenarios, while Class 3 vests offer the highest visibility and protection, especially in high-risk environments. By understanding the nuances of each class, you can ensure that your workforce remains visible and safe, contributing to a more secure working environment.